If you're fascinated by process and how something as magical as a mer tail actually comes into being, you'll like this part of the interview. Thanks again, stillwater_fx, for sharing all this great information and the marvelous photos!

asakiyume How did you first learn about making mermaid tails?

stillwater_fx For me, the moment I saw the practical props used in the movie The Thirteenth Year, by Disney, the tail and the arm fins in that movie were wearable items. When I realized that, I instantly thought about how I would have to wear one for me. And living in Puerto Rico, I already had a tropical paradise that most of us dream of: not even a mile away from my house was the beach.

In The Thirteenth Year, a boy realizes he's actually a mer person ... one hint--the scales appearing on him

A mermaid from the movie

And so I did the only I did the only thing that I knew to do. I dove online and I started looking for information about how to sculpt and all the information I could find on creature production and movie films. I found lots of information. I basically learned by reading: I taught myself; I found all the information about making sculptures, molding masks with latex, and props. It was grueling; I had to go through many hundreds of pages and forms and sites. Not all of it was complete; I had to make my own conclusions and connect the dots here and there. But eventually I started experimenting—small experiments, of course, because the materials are expensive for making mermaid tails, which is why the tails themselves are expensive. I’ve made many experiments. I’ve failed, and learned, and here I am today, making tails for people.

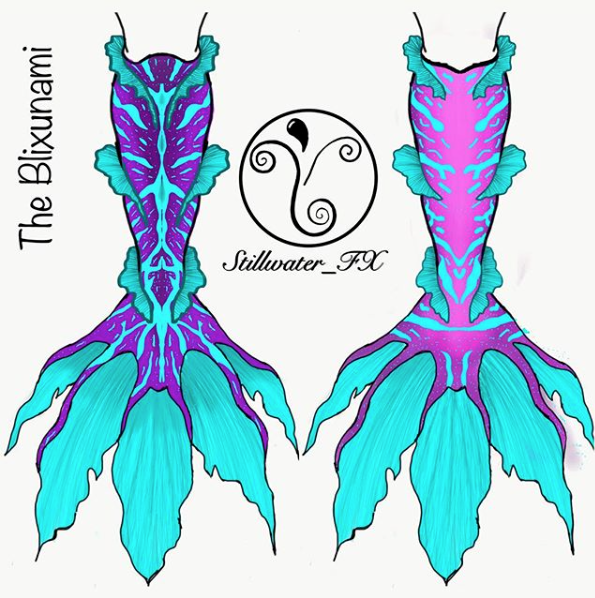

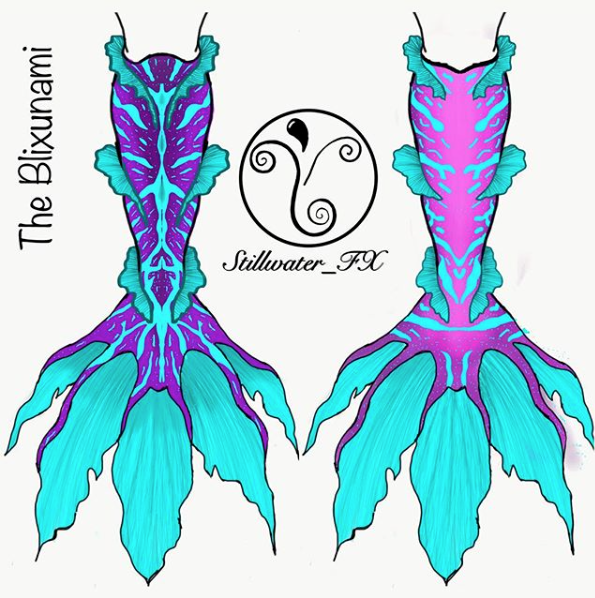

Stillwater_fx A silicone mermaid tail can be simple or very extravagant, with many fins or simple scales and a caudal fin [tail fin]. But before things can look fancy, they look like a blob of clay. And even before that, before the clay gets sculpted, it’s just an idea, a feeling in someone’s heart—maybe even my own. Then you put it onto paper, and then you can start.

Designing—tail-making process breakdown, step 1

In this step, we develop the idea based on the merperson’s style and personality. This is where you chat with the client about what colors they favor, what their “mer-sonality” is, and how it will be expressed through the way the fins are shaped and how the colors are combined to form patterns and shapes. Some fishfolk want to look like a warrior. Others want to look like a princess. It is my job to bring all their ideas into one cohesive design and present it to the customer in hopes that they love it as much as I do. Other times the client is completely prepared and has a specific design in mind, drawn out and colored for you.

Sculpting—tail-making process breakdown, step 2

In order to make a mermaid tail, one must first sculpt all the individual pieces, and this part of the process is usually the longest to complete. Depending on the design of the tail, the tail can have up to four sets of fins. There are three main types of fins for mermaid tails: First is the pectoral fins; second, the heel fins; and third and the largest usually, is the dorsal fin.

When sculpting non-symmetrical fins, you must first sculpt both sides, like the front and the back of your hand, for example. In this way the texture is on both sides of the fin. The shape, texture, and thickness of the fins is all dependent on the style the client is going for. If they want flowy fins, like seaweed, I sculpt them thin, so when they’re in the water they bend and flow with the mermaid’s movement, thus making them look very graceful. But honestly, for me, sculpting is the longest part of the process, mostly because I’m always obsessing over symmetry and everything looking perfect.

A clay sculpture for the caudal fin

Molding—tail-making process breakdown, step 3

After every piece of the tail had been sculpted, the mold-making processes can begin. The most commonly used molding medium is plaster. I personally use plaster of Paris, and you can find this at your local Home Depot.

To begin, you must first build walls around your sculpture. I use clay to build up the walls. They work as a sort of dam to prevent the plaster from falling out. Using clean cold water, you mix plaster powder into water. To avoid the bubbles, sprinkle plaster onto the surface of the water allowing it to sink slowly to the bottom of the bucket. Once enough plaster’s in the water, give it a good mix until you get that pancake mix consistency. The plaster is on a running clock from the moment it’s mixed with water. The chemical reaction will cause the mix to warm up and harden. I delay this process by adding the mix with cold water, thus giving myself a bit more working time.

Begin pouring slowly at the lowest point and allow the plaster to slick its way up and into all the grooves and details of the sculpture. After you’re finished pouring and the entire sculpture is submerged in plaster, begin vibrating the base of the mold. You shake it in order to remove all the bubbles that might later ruin the detail you worked on. If enough bubbles are left inside the mold, and they form a line, later, with enough impact, they might shatter it or break your mold. After you have completed this process and you feel that all the bubbles have been lifted from the sculpture, then you wait at least 24 hours. It usually hardens faster than that if it’s a small mold, but I usually like to give it at least 24 hours in order to let it sweat out all the excess water that it may have within, and after the 24-hour mark it’s usually hardened to its maximum properties.

Plaster casts

Casting—tail-making process breakdown, step 4

After the mold is hardened and dried, it’s time for casting the fins and scales for putting the tail together. Some people use a body form, like a mannikin, and build the tail on top of that. I buy the silicone from smooth-on.com. Their dragon skin series is the most adapted for the tail-making process. Its durability and strength is unparalleled by any other rubber in the market today. This means that you can stretch it, fold it, and bend it, and it will not tear or rip.

First, you must prepare the mold by applying a release agent so that the silicone does not stick to the mold itself. Next, you must mix the silicone. Before the silicone turns into a solid rubber, it has two component liquids, with a part A and a part B. You pour equal amounts into a clean container, mix thoroughly, and then add the base pigment.

silicone

Once fully mixed, it is time for pouring the gel liquid into the mold of our sculpture. This means you pour the silicone into the negative. Again, just like the plaster before, you must start at the lowest elevation of the mold, allowing the silicone to slick its way up into all the shapes. This avoids any bubbles from forming. Depending on the type of silicone that you bought, there may be different waiting times. Some of the silicones, like dragon skin 20 medium, is a medium curing speed, as it says. So this means that you would have about a 20- to 25-minute work time. Others are fast or slow, so they cure faster or they harden slower, so you may have more time to work with your project. So depending on what you’re working with, you can pick just the right type of silicone to work at your speed and pace you want.

After you pour every piece, just let them sit and cure for at least 24 hours until they’re hardened, and then you remove them, and you have a positive—basically a replica of the sculpture you made, perfectly, in perfect detail. And you can reproduce your sculpture many hundreds of times as long as you have the mold of it.

A finished caudal fin

A dorsal fin with the original design

Applying scales

Any questions? Leave them here! And...

STAY TUNED FOR PART 3: FAVORITE PARTS, HARDEST PARTS, AND SWIMMING IN A TAIL

asakiyume How did you first learn about making mermaid tails?

stillwater_fx For me, the moment I saw the practical props used in the movie The Thirteenth Year, by Disney, the tail and the arm fins in that movie were wearable items. When I realized that, I instantly thought about how I would have to wear one for me. And living in Puerto Rico, I already had a tropical paradise that most of us dream of: not even a mile away from my house was the beach.

A mermaid from the movie

And so I did the only I did the only thing that I knew to do. I dove online and I started looking for information about how to sculpt and all the information I could find on creature production and movie films. I found lots of information. I basically learned by reading: I taught myself; I found all the information about making sculptures, molding masks with latex, and props. It was grueling; I had to go through many hundreds of pages and forms and sites. Not all of it was complete; I had to make my own conclusions and connect the dots here and there. But eventually I started experimenting—small experiments, of course, because the materials are expensive for making mermaid tails, which is why the tails themselves are expensive. I’ve made many experiments. I’ve failed, and learned, and here I am today, making tails for people.

Stillwater_fx A silicone mermaid tail can be simple or very extravagant, with many fins or simple scales and a caudal fin [tail fin]. But before things can look fancy, they look like a blob of clay. And even before that, before the clay gets sculpted, it’s just an idea, a feeling in someone’s heart—maybe even my own. Then you put it onto paper, and then you can start.

Designing—tail-making process breakdown, step 1

In this step, we develop the idea based on the merperson’s style and personality. This is where you chat with the client about what colors they favor, what their “mer-sonality” is, and how it will be expressed through the way the fins are shaped and how the colors are combined to form patterns and shapes. Some fishfolk want to look like a warrior. Others want to look like a princess. It is my job to bring all their ideas into one cohesive design and present it to the customer in hopes that they love it as much as I do. Other times the client is completely prepared and has a specific design in mind, drawn out and colored for you.

Sculpting—tail-making process breakdown, step 2

In order to make a mermaid tail, one must first sculpt all the individual pieces, and this part of the process is usually the longest to complete. Depending on the design of the tail, the tail can have up to four sets of fins. There are three main types of fins for mermaid tails: First is the pectoral fins; second, the heel fins; and third and the largest usually, is the dorsal fin.

When sculpting non-symmetrical fins, you must first sculpt both sides, like the front and the back of your hand, for example. In this way the texture is on both sides of the fin. The shape, texture, and thickness of the fins is all dependent on the style the client is going for. If they want flowy fins, like seaweed, I sculpt them thin, so when they’re in the water they bend and flow with the mermaid’s movement, thus making them look very graceful. But honestly, for me, sculpting is the longest part of the process, mostly because I’m always obsessing over symmetry and everything looking perfect.

Molding—tail-making process breakdown, step 3

After every piece of the tail had been sculpted, the mold-making processes can begin. The most commonly used molding medium is plaster. I personally use plaster of Paris, and you can find this at your local Home Depot.

To begin, you must first build walls around your sculpture. I use clay to build up the walls. They work as a sort of dam to prevent the plaster from falling out. Using clean cold water, you mix plaster powder into water. To avoid the bubbles, sprinkle plaster onto the surface of the water allowing it to sink slowly to the bottom of the bucket. Once enough plaster’s in the water, give it a good mix until you get that pancake mix consistency. The plaster is on a running clock from the moment it’s mixed with water. The chemical reaction will cause the mix to warm up and harden. I delay this process by adding the mix with cold water, thus giving myself a bit more working time.

Begin pouring slowly at the lowest point and allow the plaster to slick its way up and into all the grooves and details of the sculpture. After you’re finished pouring and the entire sculpture is submerged in plaster, begin vibrating the base of the mold. You shake it in order to remove all the bubbles that might later ruin the detail you worked on. If enough bubbles are left inside the mold, and they form a line, later, with enough impact, they might shatter it or break your mold. After you have completed this process and you feel that all the bubbles have been lifted from the sculpture, then you wait at least 24 hours. It usually hardens faster than that if it’s a small mold, but I usually like to give it at least 24 hours in order to let it sweat out all the excess water that it may have within, and after the 24-hour mark it’s usually hardened to its maximum properties.

Casting—tail-making process breakdown, step 4

After the mold is hardened and dried, it’s time for casting the fins and scales for putting the tail together. Some people use a body form, like a mannikin, and build the tail on top of that. I buy the silicone from smooth-on.com. Their dragon skin series is the most adapted for the tail-making process. Its durability and strength is unparalleled by any other rubber in the market today. This means that you can stretch it, fold it, and bend it, and it will not tear or rip.

First, you must prepare the mold by applying a release agent so that the silicone does not stick to the mold itself. Next, you must mix the silicone. Before the silicone turns into a solid rubber, it has two component liquids, with a part A and a part B. You pour equal amounts into a clean container, mix thoroughly, and then add the base pigment.

Once fully mixed, it is time for pouring the gel liquid into the mold of our sculpture. This means you pour the silicone into the negative. Again, just like the plaster before, you must start at the lowest elevation of the mold, allowing the silicone to slick its way up into all the shapes. This avoids any bubbles from forming. Depending on the type of silicone that you bought, there may be different waiting times. Some of the silicones, like dragon skin 20 medium, is a medium curing speed, as it says. So this means that you would have about a 20- to 25-minute work time. Others are fast or slow, so they cure faster or they harden slower, so you may have more time to work with your project. So depending on what you’re working with, you can pick just the right type of silicone to work at your speed and pace you want.

After you pour every piece, just let them sit and cure for at least 24 hours until they’re hardened, and then you remove them, and you have a positive—basically a replica of the sculpture you made, perfectly, in perfect detail. And you can reproduce your sculpture many hundreds of times as long as you have the mold of it.

A dorsal fin with the original design

Applying scales

Any questions? Leave them here! And...

STAY TUNED FOR PART 3: FAVORITE PARTS, HARDEST PARTS, AND SWIMMING IN A TAIL

no subject

Date: 2020-04-23 09:08 pm (UTC)no subject

Date: 2020-04-23 09:11 pm (UTC)no subject

Date: 2020-04-23 10:04 pm (UTC)I love not just the step-by-step view on the work, but the glimpses of different designs. That blue-and-orange pattern is beautiful.

no subject

Date: 2020-04-23 10:31 pm (UTC)no subject

Date: 2020-04-25 07:04 pm (UTC)no subject

Date: 2020-04-25 07:06 pm (UTC)no subject

Date: 2020-04-27 01:02 am (UTC)no subject

Date: 2020-04-25 09:35 pm (UTC)It's wonderful! If you ever do make it, I look forward.

(And hello!)

no subject

Date: 2020-04-24 04:49 am (UTC)no subject

Date: 2020-04-24 11:40 am (UTC)(And you're very welcome!)

no subject

Date: 2020-04-24 10:08 pm (UTC)But! If you want it to be a username from another site, you can also add in site="whatever.com" inside the brackets. I suspect DW may have to have that site enabled to get the little icon thingy to show up right, but as far as I can tell they have most of the usual social media sites (and probably several I've never heard of) enabled if so.

And thus:

[user name="asakiyume"] (no site specified) ->

[user name="asakiyume" site="livejournal.com"] ->

[user name="stillwater_fx" site="instagram.com"] ->

[user name="genarti" site="archiveofourown.org"] ->

[user name="ryfkah" site="twitter.com"] ->

etc!

no subject

Date: 2020-04-24 10:37 pm (UTC)no subject

Date: 2020-04-25 07:08 pm (UTC)I love seeing the smiles of the people I create for knowing that I did a part in making someone's dream come true!

no subject

Date: 2020-04-24 04:07 pm (UTC)no subject

Date: 2020-04-25 02:18 pm (UTC)